1. Choose the RIGHT BLADE for resawing.

As you saw through very thick stock, each saw tooth shaves out an enormous amount of waste. In order

to maintain a reasonably productive feed rate, there has to be room out of the way for the waste to

occupy until the tooth emerges from the cut. (Otherwise the gullets between the teeth fill up and

stall further advance until they've cleared the stock.) Blades with about 3 teeth per inch (tpi)

have large gullets which can accommodate as much waste as you'll generate by sawing through thick

stock, and they'll handle anything less substantial with no trouble at all. The best choice of all

is our

Wood Slicer

, whose thin-kerf, variable pitch 3-4 tpi design makes it the smoothest and

quietest resaw blade on the market.

Now, how wide should the blade be? In principle, the wider the blade, the higher its beam strength

and the better it can maintain straightness. Wider, however, isn't necessarily better. Almost all

U.S. woodcutting bandsaw blades over 1/2" wide are made of coil stock .035" thick (which by itself

is thicker than the Wood Slicer's TOTAL kerf width – including the width added by the set of the

teeth). Most 3/4" blades are set far more coarsely as well. They more than double the load on your saw,

and they cut so roughly that on medium-sized bandsaws (14" and smaller), they're clearly a step in

the wrong direction. (Consider a 3/4" wide blade only if your bandsaw is an 18" model or larger.)

2. TENSION the blade for optimal performance.

Adequate blade tension helps keep stock centered even if your control isn't flawless, and it reduces

the blade's tendency to flutter under thrust. It's easy to set a satisfactory amount of tension.

Install a Wood Slicer blade on your saw with lateral guides and thrust bearings OPENED UP AND BACKED

OFF both above and below the table so they do not contact the blade. With the saw unplugged, crank

on some tension and then carefully give the blade a sharp sideways poke with your index finger about

halfway between the upper and lower wheels. The blade will deflect a short distance and then seem to

hit a wall; if you push a lot harder it will bend farther, but there's a fairly distinct point where

it quits deflecting easily.

Now add tension until this sideways movement is just 1/4" to 5/16" on saws

with 6" depth of cut, or about 3/8" to 1/2" on saws with 12" depth. By the way, don't look at the

saw's built-in tension gauge until you're finished; there's no need to confuse yourself with

arbitrary numbers. After you've gotten the hang of tensioning by feel, check the gauge and use its

reading as a setup guide when tensioning the blade in the future.

Now track your blade on the upper wheel so the deepest part of the gullet of the

blade is at the centerline of the tire. This usually gives the best results

for the blade to continue tracking well while cutting.

3. Adjust your BLADE GUIDES.

Once the blade is tensioned and tracking properly, there's still some tuning you can do that can

make a real difference in performance. So before you bring the lateral guides and

thrust bearings

up

close to the blade, close the wheel covers, plug in the saw and turn it on. First make sure the

blade tracks well at full speed, adjusting the tracking setting as necessary.

Now observe the blade. If vibration blurs the blade, try increasing or decreasing the tension very

slightly until the blade runs smoothly in a straight, quiet line from wheel to wheel. Cuts will be

smoother when you eliminate this source of fluttering in the kerf, and the saw will run quieter and

more efficiently as well.

Now you're ready to bring your lateral blade guides and rear thrust bearings close to the blade. By

the way, does your saw use traditional steel blade guides, or the more modern roller guides? If it

uses traditional steel guides, do yourself a favor and replace them with

Cool Blocks

, which are

blade guides made of graphite-impregnated phenolic resin. Unlike metal blade guides, they can be

snugged right up against the blade and give you a far more stable and accurately guided cut. Cool

Blocks eliminate friction and heat caused by metal to metal contact so the blade runs smoother,

cooler and far quieter than with metal guides. Best of all, Cool Blocks will pay for themselves

quickly by extending the life of your bandsaw blades.

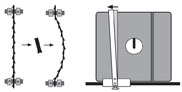

4. Steering your workpiece: Use a POINT BLOCK to guide your cut.

Cutting straight lines is easy: you just need to find out how the saw wants to do it, and do it that

way. Every bandsaw blade, unless there's something seriously wrong, can cut straight lines, but each

will do so in its own way. A particular blade has its own "lead angle," which may be different from

"straight ahead." For this reason, if you're resawing just one or two pieces, it may be easiest to

use a point block fence, a curved fence tall enough to hold your stock upright while leaving feed

direction manually up to you. Mark the cut line full length on the stock (leaving a generous margin

for error), set the point block to your target width and freehand the cut, adjusting feed direction

as you go. It's an imperfect technique; you'll waste more wood and spend more time at the thickness

planer than ideal, but overall you'll get the job done quickly.

Cutting straight lines is easy: you just need to find out how the saw wants to do it, and do it that

way. Every bandsaw blade, unless there's something seriously wrong, can cut straight lines, but each

will do so in its own way. A particular blade has its own "lead angle," which may be different from

"straight ahead." For this reason, if you're resawing just one or two pieces, it may be easiest to

use a point block fence, a curved fence tall enough to hold your stock upright while leaving feed

direction manually up to you. Mark the cut line full length on the stock (leaving a generous margin

for error), set the point block to your target width and freehand the cut, adjusting feed direction

as you go. It's an imperfect technique; you'll waste more wood and spend more time at the thickness

planer than ideal, but overall you'll get the job done quickly.

5. Better yet, adjust your fence to the LEAD ANGLE of the blade.

When you need to resaw more than a couple of pieces, however, it will probably be more productive to

set up a straight fence and make the cuts with predictable, repeatable accuracy, minimizing waste

and finishing time. However it doesn't necessarily help to set your rip fence parallel to your miter

slot or perpendicular to the front edge of your table. You want to be able to adjust your fence to

skew right or left at least 1/2" out of parallel to the miter slot. If because of its design, your

fence cannot be adjusted to skew right or left, you can make your own, or upgrade instead to

our

Kreg Precision Bandsaw Fence

which is fully adjustable. Outfit your fence with an auxiliary face high

enough to hold your resaw stock securely vertical – 5" or 6" should do.

When you need to resaw more than a couple of pieces, however, it will probably be more productive to

set up a straight fence and make the cuts with predictable, repeatable accuracy, minimizing waste

and finishing time. However it doesn't necessarily help to set your rip fence parallel to your miter

slot or perpendicular to the front edge of your table. You want to be able to adjust your fence to

skew right or left at least 1/2" out of parallel to the miter slot. If because of its design, your

fence cannot be adjusted to skew right or left, you can make your own, or upgrade instead to

our

Kreg Precision Bandsaw Fence

which is fully adjustable. Outfit your fence with an auxiliary face high

enough to hold your resaw stock securely vertical – 5" or 6" should do.

Now take a piece of 8/4 scrap wood two or three feet long, joint an edge straight, and mark a line

parallel to that edge. Rip (not resaw) freehand along the line, adjusting your feed direction until

you're cutting consistently straight down the line. When you've split the line for 4 or 5 inches,

stop. Hold the stock still on the table and shut off the saw. Mark a pencil line (which can be

erased later) on the saw table along the straight edge of the test piece, then SET YOUR RIP FENCE

PARALLEL TO THE PENCIL LINE. This is a first approximation to get you ready for fine tuning.

Now make a SHORT RESAW CUT, either in the work at hand or scrap of similar hardness and roughly similar

width. With the cut completed, stand a straightedge against the resawn face of the board. You may

see that the blade bowed left or right within the stock. The way the blade bowed tells you how to

fine tune your fence for very precise resawing. You know that the solid body of a blade can't simply

move sideways through solid wood. To create a bowed cut, the teeth must lead to one side or the

other within the wood (where they're free of the lateral guides' constraint), twisting the blade and

making it saw its way out of vertical.

To keep the cut vertical, adjust your fence to match the way

the blade twisted. If the blade bowed to the left, adjust the far end of your fence slightly to the

right; if the blade bowed right, adjust the far end of your fence slightly to the left. Make another

test cut and check the face of the wood again. It may take three or four tests to get the fence set

for flawless sawing, but once that's done you can resaw piece after identical piece, with cuts so

straight that one pass through the planer is all its takes to produce clean, flat wood at your

target thickness.

6. Feed at the RIGHT RATE.

Once you've done all of the above successfully, you can't go wrong – unless you feed too fast or too

slow, or let the blade get good and dirty. Feeding too slowly will cut the wood okay, but it will

wear out the blade a lot faster than need be. You're feeding too fast when the completed cut shows

pronounced bands of wide diagonal tooth marks. Practice feeding at a moderate, consistent pace, just

slow enough to leave a smooth surface.

7. Keep your blade CLEAN.

Several species of timber can cause rapid buildup of debris on the blade, and any wood eventually

will bake on quite a load. Material crusted around the teeth will invariably make it as hard for

them to cut as if they were dead dull, and it can affect the blade's lead angle, too. The longer you

wait to clean a blade the harder it will be, so clean it often. If a quick scrub with a

Scotch-Brite pad

laced with mineral spirits doesn't do the trick, take the blade off the saw and hose it down

with our

Blade & Bit Cleaner

, wait a few minutes and then wipe clean. If you saw resinous wood

regularly,

with our

BladeCote blade treatment

will help retard accumulation of resins and junk.

8. Do it SAFELY.

There's one last detail to cover. Keep your fingers attached. The bandsaw may be the least hazardous

resawing tool in the shop, but always remember that anything that turns hard wood into sawdust can

do much worse to you. As you resaw, you'll often find yourself pushing the stock with one hand while

holding it against the high face of your rip fence with the other. It's tempting to let your

pressure hand slide along toward the neighborhood of the blade. Bad idea! Imagine the blade bowing

within the wood and unexpectedly sawing its way out through the face your hand is pressed against.

Likewise, it can also be tempting to push the wood right up to the last half inch and then pull it

through the final bit of the cut. Once again, imagine the worst case where an unseen crack allows

the last two or three inches of the plank to split apart suddenly, just as you're pushing firmly

toward the blade. Always use a push block instead. (You can easily make one out of a scrap of wood.)

There's plenty more to know about resawing, but this should help get you started successfully.

And don't worry. Perfection will come with practice.