|

Quite often we receive questions from customers prefaced by "Please don't tell anyone I asked you this, but..." or "I'm embarrassed to admit I don't know this, but..." or "I've been woodworking since high school shop class, but I don't know..."

So this month we've decided to address several of those nagging little questions that you just can't bring yourself to ask your woodworking buddies.

Question:

What exactly is a board foot?

Question:

What exactly is a board foot?

How do I determine the number of board feet in a piece of wood?

Answer:

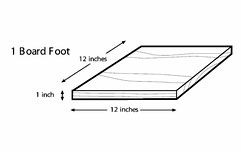

A board foot is a common unit used for measuring lumber. It is equal to 144 cubic inches, or the volume of a board 1 foot long x 1 foot wide x 1 inch thick. Therefore, to calculate board feet use the following formula:

One board foot = Thickness (inches) x Width (inches) x Length (feet) / 12

For example, a piece of wood measuring 2" thick by 12" wide by 10' long =

2 x 12 x 10 = 240

240/12 = 20 BF

Question:

What is a good food-safe finish?

What finish should I use on children's toys?

Answer:

Shellac is very durable, a beautiful finish and very safe; in fact, it is USDA approved for sealing fruits, vegetables, candy and medications. However, all finishes sold in the U.S. are safe once they are dried and cured. The same goes for stains. Once the solvents have evaporated, any cured film is safe for contact with food. This does not mean that the finish itself is safe to consume; it simply means that additives such as heavy-metal driers and plasticizers are encapsulated well enough when the finish is dried that they do not leach out. (If you wanted to go with something that's food safe throughout the

whole

process, you could use shellac that you've dissolved in 190-proof alcohol from the liquor store.) The key is to allow the appropriate drying and curing times for a finish. Follow the manufacturer's instructions and when in doubt, request an MSDS (Materials Safety Data Sheet).

Question:

I frequently see wood sold as 4/4, 5/4, 6/4, etc., or hear it referred to as "four-quarter", "eight-quarter", etc. What does that mean?

Answer:

Wood is often listed like this as dealers and lumber yards measure the thickness of the material in fours or quarter of an inch increments. Therefore, 4/4 or "four-quarter" is one inch thick, 6/4 is one and a half inches thick, 8/4 is two inches thick, etc.

Question:

What is "nominal size" and why is it smaller than the actual size of the wood I bought?

Answer:

The nominal size of a board is calculated based on its rough size before drying and planing. The shrinkage which occurs as the board is dried and the planing result in the final lumber size being slightly smaller in thickness and width than the nominal size.

Question:

What is "dimensional lumber"?

What does "S4S" mean?

Answer:

Dimensional lumber is a term used to refer to lumber that is cut to a standardized width and depth specified in inches. For example, 2 x 4 (or two-by-four), 2 x 6, 4 x 4, etc. S4S stands for "surfaced on 4 sides", meaning that the material is finished on all four sides. Dimensional lumber is commonly S4S. S4S finished lumber and dimensional lumber are labeled according to nominal size, or the size of the rough board before it was planed smooth.

Question:

I just bought a new bandsaw blade, but when I

tried to install it I noticed the teeth were facing up instead of down. I cant figure out what's

wrong can you help?

Answer:

Sometimes when

the band is welded the technicians forget to turn the blade right side out after joining the band

together, or in uncoiling the blade you may inadvertently flip it inside out. All you need to do is

to twist or flip the blade right side out. This will reverse the direction of the teeth so they

will be pointing down when you mount the blade on your bandsaw.

Did you know we stock

over 200

different sizes of bandsaw blades

(as well as

over 300

different router bits)

to fit every woodworking need?

Question:

What is the "Golden Ratio"? Why is it referred to so much in woodworking and furniture design?

Answer:

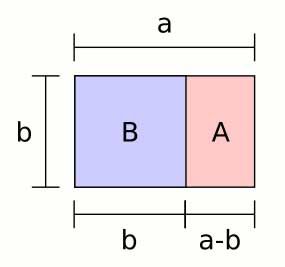

The golden ratio, also known as the golden mean, golden number, golden proportion, divine proportion and classical proportion, is a proportioning system that has been found to produce aesthetically pleasing shapes. The ratio is represented by the following formula:

A is to B as B is to A + B

or,

A/B = B / (A + B)

A is to B as B is to A + B

or,

A/B = B / (A + B)

For woodworking, the following rule may be used:

1st dimension x 1.62 = 2nd dimension

2nd dimension + 1st dimension = 3rd dimension

Or, if height is known:

H x 1.62 = W and H + W = L

If width is known:

W / 1.62 = H and H + W = L

If length is known:

L / 1.62 = W and W / 1.62 = H

Question:

I know what a dovetail joint is, but what is a "blind" or "half-blind" dovetail?

Question:

I know what a dovetail joint is, but what is a "blind" or "half-blind" dovetail?

Answer:

In a plain (or through) dovetail joint, the end grain of both boards is visible when the joint is assembled. In half-blind (or lapped) dovetail joints, the end-grain of one of the boards cannot be seen in the assembled joint, and in a blind dovetail joint, the end-grain is not visible on either board.

Half-blind dovetails are commonly used to fasten drawer fronts to drawer sides, where it is not desireable for the end grain to be visible from the front of the cabinet, rather than attaching false fronts to drawers constructed using through dovetails. Blind dovetails are used when the strength of a dovetail is required, but the woodworker does not want end-grain to be visible at all in the finished piece.

Question:

What is the difference between "Flat Top", "ATB", and "Combination Tooth" saw blades and which kind should I use?

Answer:

Flat Top

teeth are used on blades made for ripping wood and are the most efficient for cutting and raking material out of the cut.

Alternate Top Bevel (ATB)

saw blades have teeth that alternate between a right and left hand bevel. The alternating beveled teeth form a knife-like edge on both sides of the blade, making a cleaner cut than flat top teeth. This configuration gives a smoother cut when crosscutting natural woods and veneered plywood.

Combination Tooth

blades have teeth that are arranged in groups of five - four ATB teeth and one FT - with a large gullet in between the groups, and are designed to do both crosscutting and ripping.

Question:

Almost every article I read about sharpening refers to "Scary Sharp"? What the heck does that mean?

Answer:

Scary Sharp is a method of sharpening woodworking tools using a sheet of glass and sandpaper instead of conventional methods such as oilstone or waterstone sharpening.

Question:

How in the world do I coil a bandsaw blade without shredding my fingers or poking my eye out?

Answer:

Once you get the hang of it, coiling a bandsaw blade is a piece of cake. We have an excellent

step-by-step illustrated tutorial

in our Library, as well as a

printable .pdf version

.

|