|

Mushrooms aren't just for eating! They can be cuddly-cute as well and make for a great turning project.

|

|

Figure 1 - Mushrooms on a log

|

I recently got hold of some fresh cherry branches around five inches in diameter. They are very green, having only been cut a couple of months ago. This, of course, presents a slight problem of splitting during the drying process, especially with the pith left in the piece. However, I'm far too impatient to wait years for the branches to dry naturally – I'm turning this green and keeping my fingers crossed. (A few days after I finished this turning, the log developed a large split from the pith, but it still looks pretty good.)

|

|

Figure 2 - Green branches from a cherry tree

|

I'm starting with a piece about 5-6" long, cutting it off on my bandsaw.

|

|

Figure 3 - Bandsawing off a 5-6" section of log

|

I'm going to turn the first mushroom on the end of the log - that is, as a continuous part of the turning. I don't want the mushroom on center, I want it off to one side, so I'll mount the blank between centers, but off-center on the end of the log. I'm hoping this will ensure that any splitting from the pith doesn't split the mushroom itself.

|

|

Figure 4 - I put the drive center off to one side

|

|

|

Figure 5 - ...so that the piece will be off-center on the lathe

|

With the workpiece mounted off-center, the tenon I cut for chuck-mounting will be off-center as well.

|

|

Figure 6 - Turning a tenon to mount the blank in a chuck

|

I've turned the tenon 3/4" long, which is longer than I need. This will make it easier to turn off the tenon when I'm done, by pulling it out of the chuck by 3/8", leaving 3/8" still gripped in the chuck.

|

|

Figure 7 - I'm making the tenon 3/4" long

|

I'm using a

Record Power SC4 Chuck

(which I think is one of the best chucks I've ever bought) with 75mm (about three inches) jaws.

|

|

Figure 8 - That tenon is definitely off-center!

|

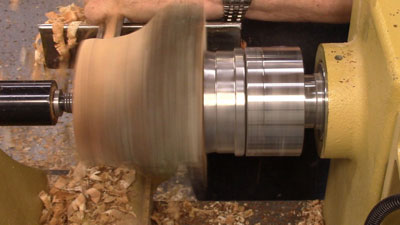

Although this blank isn't all that large, I still can't speed the lathe up too fast, because of the vibration from the off-center positioning. For this piece, the maximum I can get is about 800 rpm, and that's even pushing it a bit.

|

|

Figure 9 - My maximum speed at this stage is only 800 rpm

|

I start off with a

roughing gouge, turning the tailstock end down to round, leaving two to three inches of bark intact on the headstock end.

|

|

Figure 10 - I start off with a roughing gouge

|

I switch to a

spindle gouge

to remove some more wood, then I switch to a skew to bring the mushroom part down to a proper mushroom-looking size.

|

Figure 11 - I bring the mushroom tenon down to size with

a peeling cut using a skew

|

I'm making the mushroom diameter about 1-3/4". The other two mushrooms that I turn (separately) will be smaller.

|

|

Figure 12 - I leave about 1-3/4" for the first mushroom

|

To shape the crown of the mushroom, I use a

3/8" spindle gouge, making the crown about an inch high.

|

Figure 13 - A 3/8" spindle gouge is just right for

shaping the mushroom crown

|

With the crown shaped, I start on the stalk.

|

|

Figure 14 - Turning the mushroom stalk

|

This is a dwarf mushroom, which everyone knows has a fat bottom (and only grows in Middle Earth).

|

Figure 15 - A dwarf mushroom's stalk has a fat bottom

and a narrow neck

|

I narrow the top of the mushroom, and then undercut the bottom surface of the crown a bit (as is stipulated in the "Official Dwarf Mushroom Turner's Rulebook").

|

|

Figure 16 - This looks good to me

|

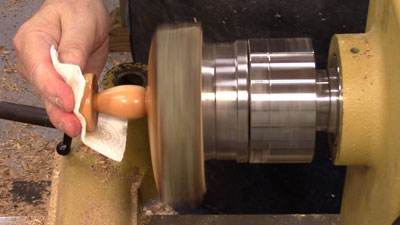

I don't expect this turning to be handled a lot, it's primarily decorative, so I'm going to use a

friction polish finish. Normally, this would yield a very shiny finish.

|

|

Figure 17 - Friction polish on a mushroom

|

However, on green wood, although the friction polish initially shines up, the moisture in the wood causes it to dull down rather quickly. I'll add a coat of wax later.

|

Figure 18 - The friction polish goes on shiny

but dulls quickly on green wood

|

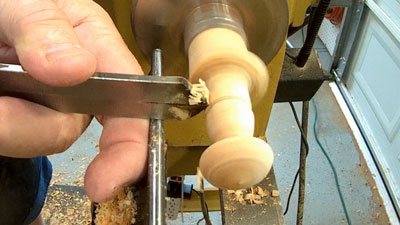

The basic mushroom is almost done. I pull the piece out of the chuck about 3/8" and tighten down the chuck again.

|

|

Figure 19 - Re-chucking to part off

|

It doesn't show all that well in the photo, but I'm using a

fluted parting tool

to part off the mushroomed log.

|

|

Figure 20 - Parting off the workpiece

|

With an off-center piece, I don't want to put my hand behind the spinning mushroom-of-death to catch it when I cut through. I stop cutting with about 1/4" of thickness left and twist it off.

|

Figure 21 - To avoid a tragic mushroom accident,

I stop parting at about 1/4"

|

|

|

Figure 22 - The first mushroom is done!

|

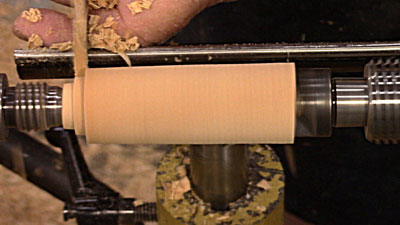

Now for the smallest mushroom. I'm using a block about 1" in cross-section and about 4" long.

|

|

Figure 23 - The blank for smallest mushroom is about 1" x 1" x 4"

|

|

|

Figure 24 - I bring it down to round with a 1" roughing gouge...

|

|

|

Figure 25 - ...and turn a tenon on one end for chuck mounting

|

With the blank now mounted in a chuck with 25mm jaws, I start shaping the crown of the mushroom and then the stem.

|

|

Figure 26 - Beginning to shape the small mushroom

|

Like the main mushroom (alpha mushroom? number one mushroom?), I make this one with a "dwarf mushroom" shape, i.e. fat at the bottom.

|

|

Figure 27 - Shaping the mushroom

|

However, unlike the alpha mushroom, I cut a 1/4" tenon at the base. This will be used to mount it on the log end.

|

|

Figure 28 - Starting a 1/4" tenon on the end

|

To size the tenon easily and quickly, I use my tenon cutter made from a 1/4" open-end wrench.

|

|

Figure 29 - Finishing the tenon cut with a dedicated tenon cutter

|

Finally, I part it off with a narrow parting tool.

|

|

Figure 30 - Parting off the small mushroom

|

Now for the middle-size mushroom – same dwarf mushroom shape, starting from a blank about 2" long and 1-1/2" in diameter.

|

|

Figure 31 - The blank for the middle-size mushroom

|

|

|

Figure 32 - Cutting the mushroom's crown…

|

|

|

Figure 33 - ...and the stalk

|

|

|

Figure 34 - …and finally a 1/4" tenon

|

|

|

Figure 35 - The finished middle-size mushroom

|

Now it's assembly time! I position the mushrooms in a staggered pattern on the log end.

|

|

Figure 36 - Arranging the mushrooms

|

Then I drill two 1/4" holes about 3/8" deep. The depth just needs to be more than the length of the tenon on the mushroom.

|

|

Figure 37 - Drilling a mounting hole

|

I use medium-viscosity

CA glue.

|

|

Figure 38 - Putting some CA glue in the mounting holes…

|

|

|

Figure 39 - Inserting the mushroom's tenon

|

And that's it! It really is a quick and easy project – well, maybe not so quick, but it's easy. And it looks great when done. (Warning! Do not try to use these mushrooms in soup!)

|

|

Figure 40 - Done!

|

If you have any questions you can email Rick at

rickandcathymorris@gmail.com.

Return to

The Highland Woodturner

front page

|